· Jesse Poteet · direct to film · 4 min read

What is DTF Printing? A New Solution for Custom Apparel

Discover how Direct-to-Film (DTF) printing offers flexibility, no minimums, and vibrant multi-color designs, perfect for custom apparel orders that demand precision and versatility.

What is DTF Printing? A New Solution for Custom Apparel

If you’ve been hearing the term “DTF” thrown around in the world of custom apparel, you might be wondering what all the buzz is about. Whether you’re a small business owner, an organization leader, or just looking to create standout custom apparel, understanding how Direct-to-Film (DTF) printing works could open up new possibilities for your next project. In this post, we’ll break down what DTF printing is, how it differs from traditional methods like screen printing, and why you might want to consider it for your next order.

What is DTF Printing?

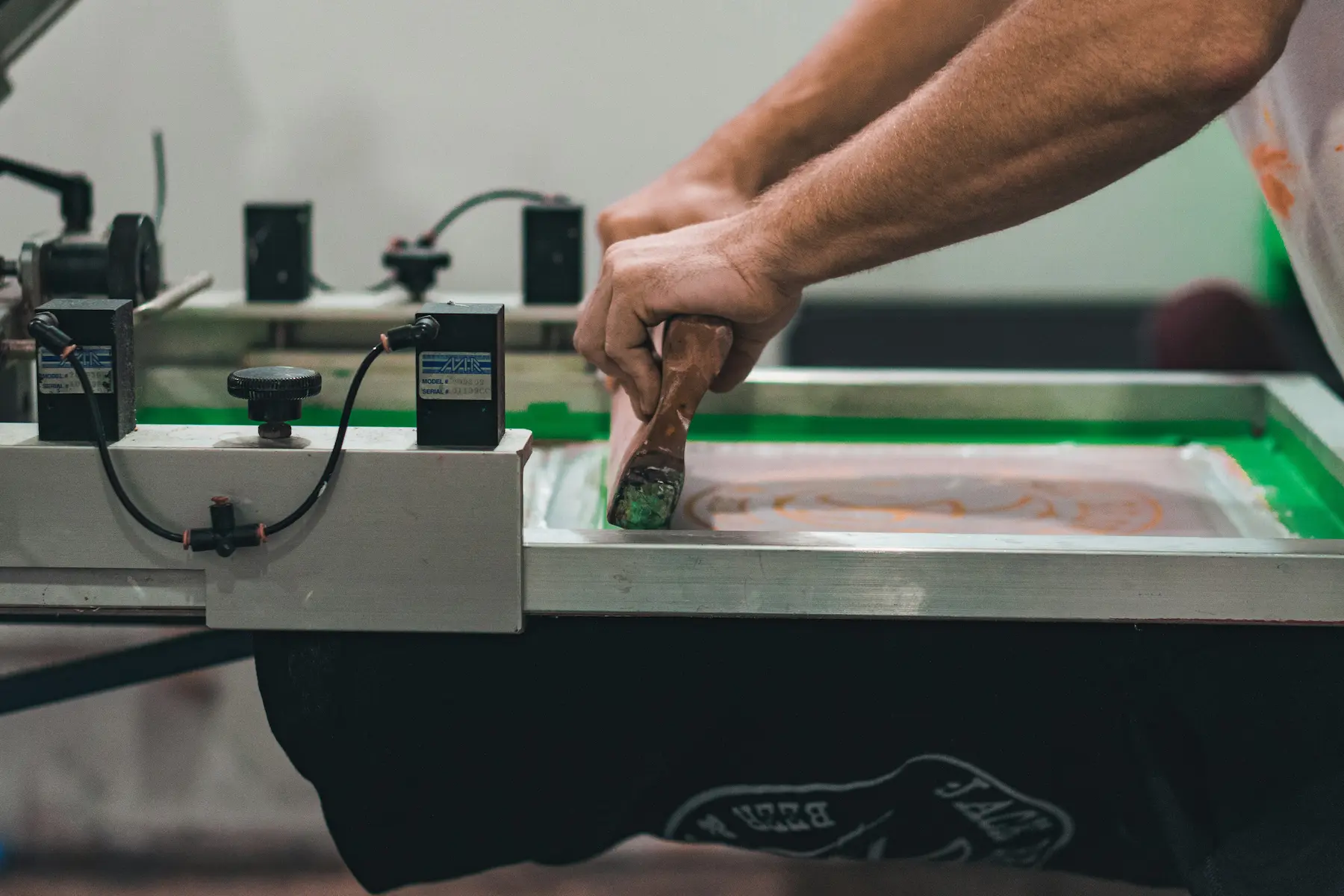

Direct-to-Film (DTF) printing is a relatively new method in the world of custom apparel decoration. Unlike traditional screen printing, where designs are printed directly onto fabric using ink, DTF prints your design onto a special film. That film is then transferred to the garment using a heat press, creating a highly durable and detailed print.

How Does it Work?

Here’s the step-by-step process:

- Design Creation: Like other printing methods, we start with your custom design.

- Print on Film: The design is printed onto a PET film using specialized inks.

- Apply Adhesive Powder: A powder adhesive is applied to the back of the film.

- Heat Press Transfer: Finally, the film is transferred onto your apparel using a heat press, which binds the ink to the fabric.

Why is DTF Popular?

DTF offers flexibility that other methods—like traditional screen printing—sometimes struggle with. Here are a few reasons why this method has gained traction:

- No Minimum Orders: Whether you need 1 item or 100, DTF works for small runs without the setup costs of traditional methods.

- Complex Designs Welcome: DTF handles multi-color, intricate, or highly detailed designs effortlessly, without needing multiple screens or layers.

- Versatile Materials: DTF works on a variety of fabrics, including polyester, cotton, nylon, and more. It even excels on tricky textures like hats or performance wear.

For an in-depth look at how DTF transfers can complement screen printing, especially on complex designs or specific items like hoodies, check out this article from ScreenPrinting.com.

How Does DTF Compare to Screen Printing?

While DTF is a game-changer for many projects, it’s important to know how it stacks up against water-based screen printing—especially when you’re deciding which method is right for your order.

Water-Based Screen Printing

Water-based screen printing has been around for decades and remains a popular choice, particularly for larger runs and eco-friendly projects. It uses water-based inks that soak into the fabric, creating a soft feel with vibrant colors, especially on lighter fabrics.

- Cost Efficiency for Larger Orders: The key to screen printing’s cost advantage is that the setup (creating screens for each color) can be spread over a larger quantity. This makes it a great choice for bigger orders, but it does require a minimum of 12 items.

- Eco-Friendly and Soft: Water-based inks are environmentally friendly and have a smooth, breathable finish on garments. They’re perfect if you want a softer print that feels like part of the fabric itself.

DTF Printing

DTF, on the other hand, doesn’t require creating multiple screens for each color in your design. Each item is printed individually, so there’s no need for minimums.

- Perfect for Small Runs and Specialty Items: If you’re working on smaller quantities or tricky fabrics (like hats or polos), DTF is your go-to. The colors are vibrant, and the print is durable, making it great for both everyday wear and promotional items.

- Higher Cost Per Item: Because each item is printed individually, DTF typically comes at a higher cost per piece compared to screen printing, especially for larger runs. However, the flexibility of no minimums and the ability to print complex designs makes it a worthwhile option for smaller or unique orders.

For more on how DTF technology has advanced, check out this breakdown of the OmniDTF printer, which highlights its impact on the custom apparel industry.

When to Choose DTF for Your Next Project

So, when should you go for DTF instead of screen printing? Here’s a quick guide:

- Small Orders: Need just a handful of shirts, hats, or polos? DTF eliminates the need for high minimums.

- Intricate Designs: If your design has multiple colors or fine details, DTF handles this effortlessly without needing multiple screens.

- Specialty Fabrics: DTF can print on materials that don’t always work well with traditional screen printing, including polyester, nylon, and textured fabrics like hats and performance wear.

Conclusion & Call to Action

If your next project needs flexibility, vibrant colors, and complex designs without the need for bulk orders, DTF might be the perfect fit. Want to see how DTF could work for your next custom apparel order? Request a quote today, and let’s bring your designs to life with this exciting new method!